Description

Genuine Accu Dyne test pens kit 30-52 are made with our reagent grade dyne testing fluids and employ a spring-loaded valve tip that keeps contaminants on the tip from affecting the accuracy of the test fluid in the test marker’s barrel.

The ACCU DYNE TEST ™ Marker Pen, is based on a valve tip applicator. The principle is simple: Keep the testing part of the pen away from the fluid storage part of the pen (in other words, no wicking from the substrate).

The diagram (right) demonstrates how that’s accomplished; by pressing the tip firmly down, the valve is opened and fresh fluid floods the tip; this flushes it clean, and allows the tester to lightly pass over the sample to accurately determine dyne level. Results are based on how long the test solution takes to form beads on the sample surface.

Accu Dyne test pens kit 30-52 supplies a complete range of Dyne Pens (which are also referred to as Corona Pens) to measure surface energy. Using a Accu Dyne test pens kit 30-52 gives quick and easy results indicating surface wettability.

Determining the surface energy can be achieved by measuring contact angle or by use of Surface Energy Test Pens (Dyne level testing).

The fluid contained within the pens is based on the ISO 8296 method for measuring the surface energy of polyethylene film.

When the Accu Dyne test pens kit 30-52 is applied to the surface, the liquid will either form a continuous film on the surface or pull back into small droplets. If the Dyne test fluid remains as a film for 3 seconds, the substrate will have a minimum surface energy of that ink value, expressed in mN/m (Dynes).

Should the Dyne test liquid reticulate or drawback into droplets in less than 1 second then the surface energy of the substrate is lower than that of the liquid itself. The exact surface energy (Dyne level) can be determined by applying a range of increasing or decreasing values of Dyne test pens

Accu Dyne test pens kit 30-52 Features

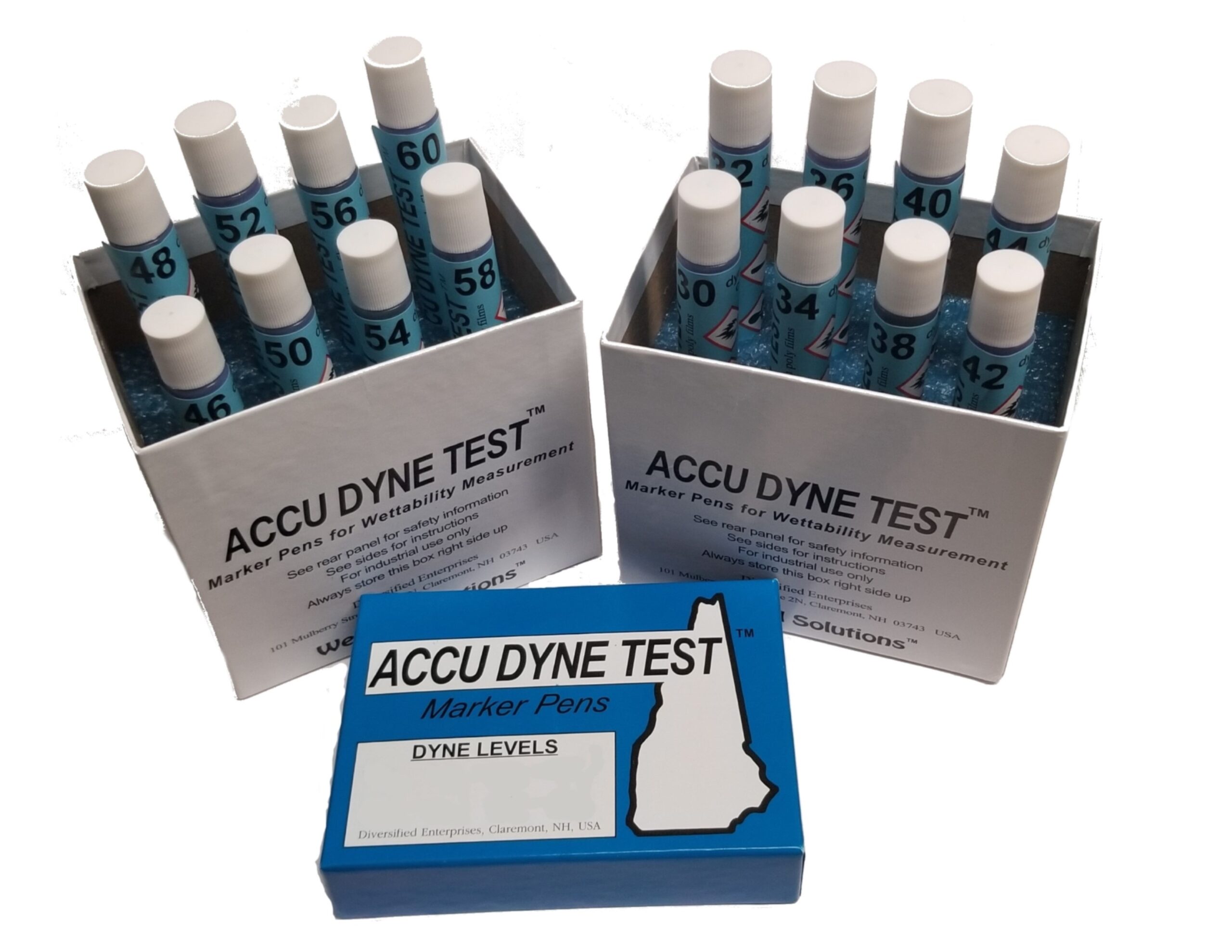

- 16 Standard levels, from 30 through 60 dynes/cm

- Specifically designed for fast, accurate online use by printers, coaters, and laminators Also ideal for process control or field use by suppliers of film, sheet, coated board, inks, coatings, and adhesives.

- Spring-loaded tip meters fluid feed and guards against contamination.

- Reliable enough for many R & D and lab applications.

- Hundreds of tests from each marker.

- Usable on virtually all smooth non-absorptive substrates.

- Six month shelf life.

- Specify any combination of dyne levels and quantities you require.

- Conveniently packaged in ready to use setup boxes.For the results of this test to be meaningful, the following four points are absolutely essential and must be followed:

Tips or Warnings

1) Do not touch or in any way contaminate the surface to be tested. Dirty surfaces lose their wettability.

2) Do not use contaminated or outdated ACCU DYNE TEST™ marker pens.

3) Never retest the same location on a sample; move along the sample, or pull a new one.

4) Store and use ACCU DYNE TEST™ marker pens at room temperature.

5) To obtain optimum adhesion, it is necessary to increase the surface energy of the substrate to just above that of the material to be applied. Surface Treatment with either Corona or Plasma results in good wetting of the material over the surface of the substrate and so improves adhesion.

.

Reviews

There are no reviews yet.